| |

- General

- Maintenance & Supply

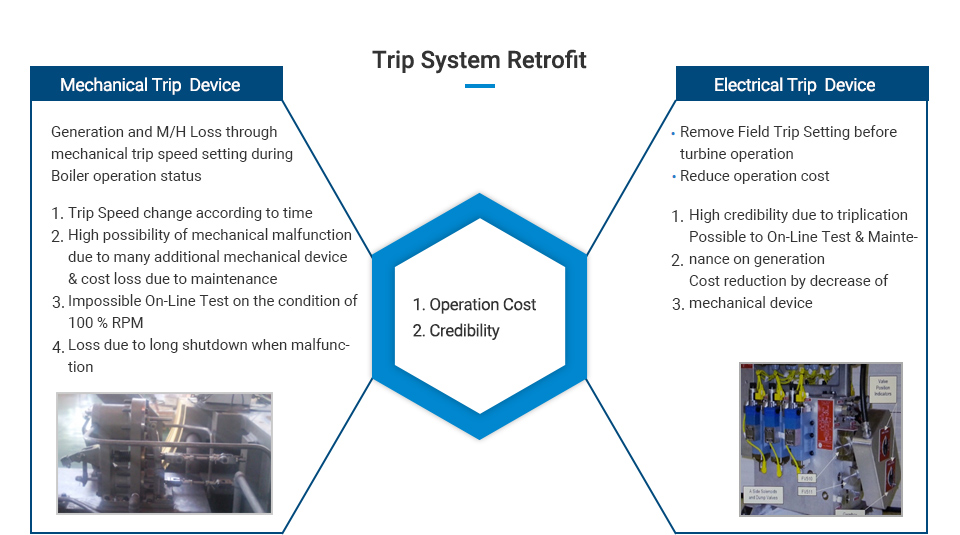

- Trip System Retrofit

- Governing System Retrofit

- Oil Flushing Equipment

| Engineering |

- CPP, NPP, CCPP Valve Actuator Maintenance & Comprehensive Performance Test

- Air Vent System Development

- Design, Manufacturing for Hydraulic Actuator of TBN

|

|

| Control system hydraulic valve maintenance and performance diagnosis |

- ETS Hydraulic valve Maintenance & Comprehensive Performance Test

- Main TBN, BFP-T(MFWP-T), Main Steam/ Feed water Sol’ Valve Maintenance & Comprehensive Performance Test

- Servo Valve Maintenance & Comprehensive Performance Test

|

| Boiler control actuator maintenance and performance diagnosis |

|

- Axial flow fan hydraulic cylinder maintenance and performance diagnosis

- Desulfurization booster fan hydraulic cylinder maintenance and performance diagnosis

|

| Development of oil flushing equipment |

- Development of TBN EHC remote controlled oil flushing system

- Development of remote controlled Oil flushing system for turbine lubricating oil system

|

|

Fossil

| Product |

Size |

| CV 1,2,3 |

Cylinder 5", 10" Stroke |

| CV 4 |

Cylinder 5", 10" Stroke |

| CV 1,2,3 |

Cylinder 6", 10" Stroke |

| CV 4 |

Cylinder 6", 10" Stroke |

| CV 1,2,3 |

Cylinder 12", 10" Stroke |

| CV 1,2,3 |

Cylinder 10", 4" Stroke |

| IV 1,2 |

Cylinder 5", 12" Stroke |

| IV 1,2 |

Cylinder 6", 12" Stroke |

| IV 1,2 |

Cylinder 7", 12" Stroke |

| IV 1,2 |

Cylinder 8", 14" Stroke |

| RSV 1,2 |

Cylinder 10", 12" Stroke(Non-Control Type) |

| RSV 1,2 |

Cylinder 8", 8" Stroke(Non-Control Type) |

| RSV 1,2 |

Cylinder 7", 8" Stroke(Non-Control Type) |

| Product |

Size |

| RSV 1,2 |

Cylinder 8", 10" Stroke(Non-Control Type) |

| RSV 1,2 |

Cylinder 10", 10" Stroke(Non-Control Type) |

| MSV 1 |

Cylinder 6", 6" Stroke(Non-Control Type) |

| MSV 2 |

Cylinder 6", 6" Stroke(Control Type) |

| MSV 1 |

Cylinder 8", 8" Stroke(Non-Control Type) |

| MSV 2 |

Cylinder 8", 8" Stroke(Control Type) |

| MSV 1 |

Cylinder 9", 8" Stroke(Non-Control Type) |

| MSV 2 |

Cylinder 9", 8" Stroke(Control Type) |

| MSV 1 |

Cylinder 9", 9" Stroke(Non-Control Type) |

| MSV 2 |

Cylinder 9", 9" Stroke(Control Type) |

| CRV |

IV# 1~2, Cylinder 5", 12" Stroke |

| CRV |

RSV# 1~2, Cylinder 4", 8" Stroke |

| LPA CV |

4-1/4"DIA.× 239.9mm Stroke(Control Type) |

Nuclear

| Product |

Size |

| CV 1,2,3 |

Cylinder 10", 14" Stroke |

| CV4 |

Cylinder 10", 12" Stroke |

| MSV 1,3,4 |

Cylinder 10", 12" Stroke (Non-Control Type) |

| MSV 2 |

Cylinder 10", 12" Stroke (Control Type) |

| IV 1,2,3 |

Cylinder 5", 14" Stroke |

| IV 4,5,6 |

Cylinder 5", 14" Stroke (Non-Control Type) |

| ISV 1~6 |

Cylinder 8", 12" Stroke (Non-Control Type) |

| TV 1,2,3,4 |

Cylinder 8", 8" Stroke |

| GV 1,2,3,4 |

Cylinder 7", 20" Stroke |

| IV 1~6 |

Cylinder 6", 10" Stroke |

| RV 1~6 |

Cylinder 6", 10" Stroke |

| |

|

| |

|

Domestic Maintenance History

| Description |

Nuclear PP |

Fossil PP |

CCPP |

Hydraulic

Actuator |

241

Actuators |

233 Actuators |

299 Actuators |

| Hydraulic Valve |

21 Plants |

60 Plants |

12 Plants |

Domestic New / upgraded equipment Supply History

| Description |

Nuclear Power |

Fossil Power |

CCPP |

| 2006 ~ 2011 |

44 Actuators |

86 Actuators |

21 Actuators |

| 2012 ~ 2014 |

20 Actuators |

16 Actuators |

7 Actuators |

| Total |

64 Actuators |

96 Actuators |

28 Actuators |

Effect of Actuator Upgrade

Trip system retrofit by replacing former mechanical trip device to reliable electric trip device can

Enhance credibility of power plant and reduce operating cost.

Governing system retrofit by replacing former mechanical governor to EHC System controlled by servo valve can enhance credibility of power plant and reduce maintenance cost.

|

| |

|