| |

|

enesG Integrity Evaluation Division is playing a role of Integrity Service and life assessment through the In-Service inspection about the main components of power plants, which is the major requirement of the Korea Institute Nuclear Safety.

As a project to prove and assure the reliability for the MRO(Maintenance, Repair, Operation) of main components, the purpose of this engineering service is to prevent any personal or material loss that may cause the breaking down of the major facilities.

|

Main Performance

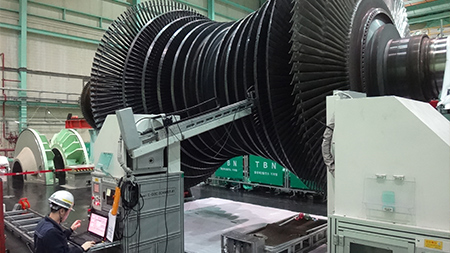

- NDT & Integrity Evaluation of TPP Turbine/Boiler Components

(TBN & GEN Rotor, Casing, Valve, Boiler etc)

- NDT & Integrity Evaluation in NPP Turbine Components

- Stress & Crack Propagation Analysis of turbine & Boiler components

- Metal Structure and Residual Life Assessment

Developing Technology

- Automatic inspection System NPP RCS

- Development of AUT/ECT System in Ω Seal Weld Area

- Development of AUT/ECT System in BMI/CEDM

- NDT & Life Assessment of Boiler components

|

|

| Automated Inspection Equipment |

| |

|

|

|

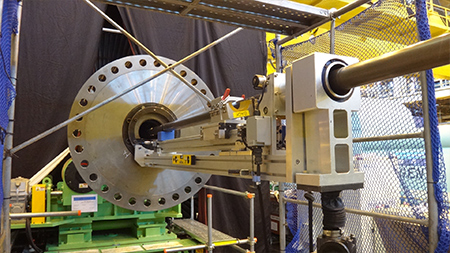

| Rotating part automated Inspection System |

|

|

|

| Bore Automated Inspection System

|

|

| |

| Boring & Honing Machine and MT Equipment |

| |

|

|

| Portable Bore Boring & Horning Equipment |

|

|

|

| 20,000Amp HWDC & FWDC MT Equipment |

|

|

|

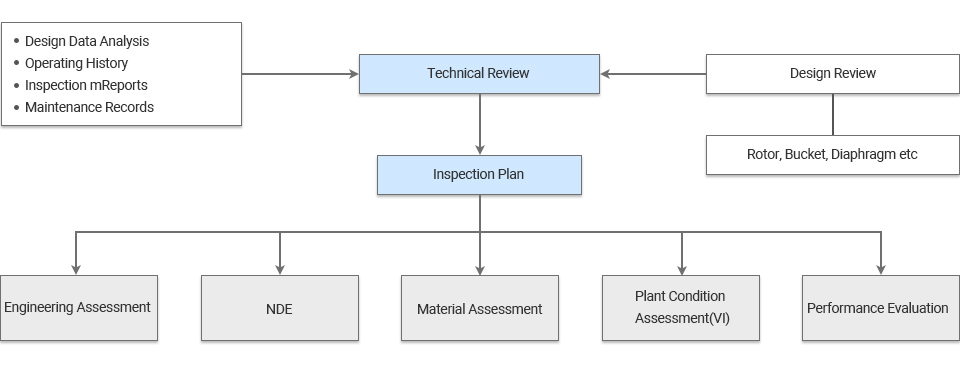

Analysis & Remaining Life Evaluation

- Design data, operating history, history of inspection and maintenance / repair history analysis performed Technical Review

- Inspection Plan is based on the Engineering Assessment, NDE, Visual Inspection, Material Assessment, Performance Assessment.

|

| |

|